Automation and Electronics has developed very sophisticated water treatment plant designs, and keeps current with evolving regulatory agency decisions. Our engineers, programmers, technicians, electricians and support staff are conscientious and motivated.

A&E provides technical expertise for large projects and small system upgrades. Our technicians train operators to improve system reliability by helping them understand system coordination procedures. Helping operations to be proactive reduces emergencies and helps promote safe, smooth, efficient operation.

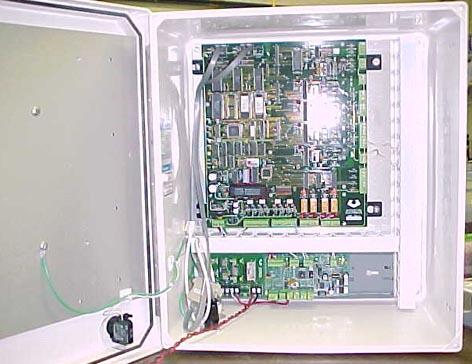

Remote system monitoring and control is one specialty area. We have decades of experience making solar powered monitor and control systems work in poor power quality conditions, extreme climate conditions, and isolated but mission critical control systems. When even redundant systems are stressed, built in warning systems alert designated personnel of the situation, and can provide alternative means of messaging, should primary contacts not be available.

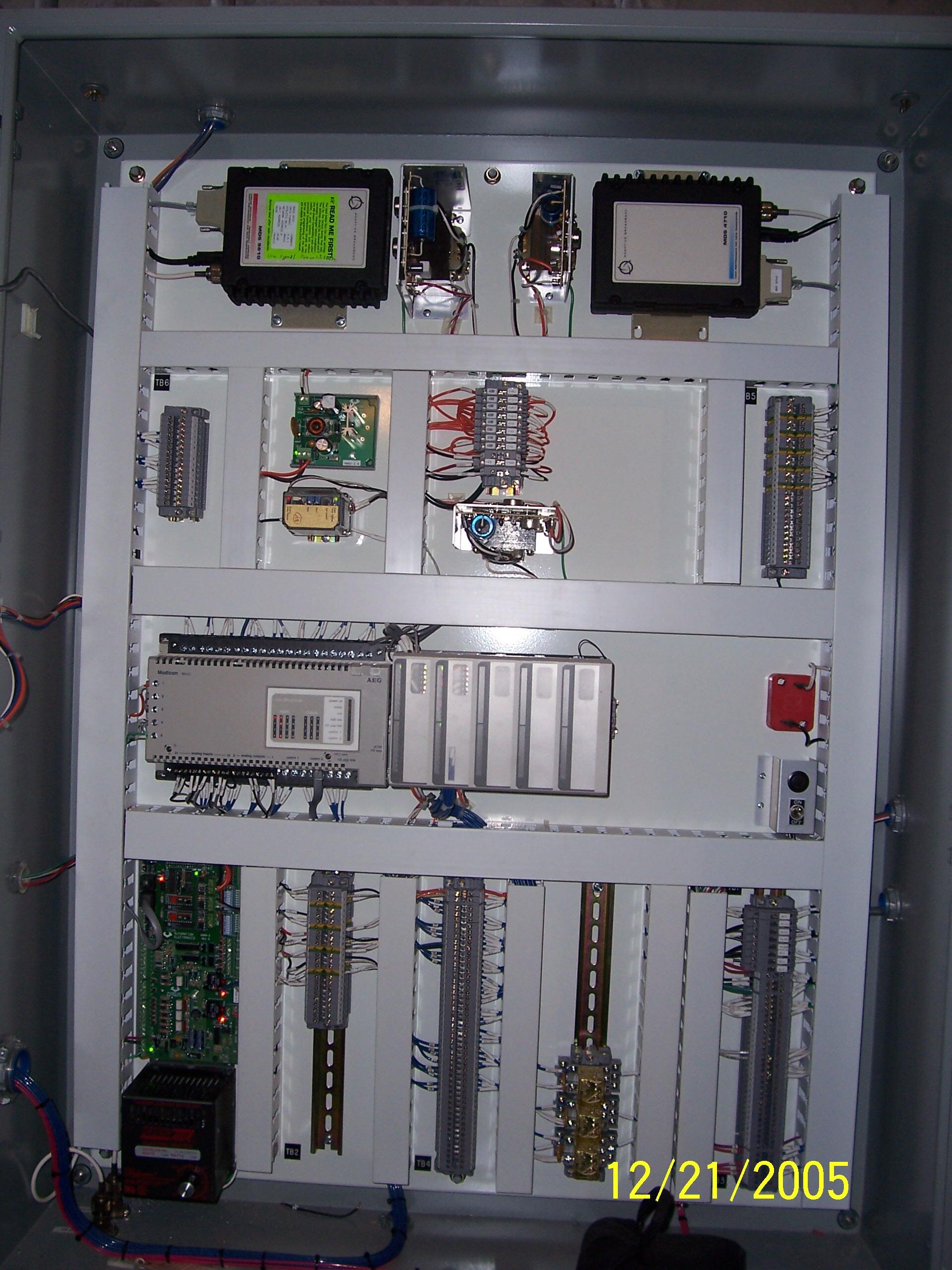

All relevant National Electrical Code requirements are met for public works projects. Documentation includes AutoDesk AutoCAD® drawings. Clear labeling of components and functions helps to make operation of even complex systems safe and intuitive.

Programmable Logic Controllers provide local control for systems, and data communication systems provide central control. PLC program documentation includes commented ladder diagrams, cross-indexed for component locations. Backup programs are provided for all PLC systems.

Remote and on site support services are available 24x7. Virtual Personal Network (VPN) support is available so authorized personnel can view operator screens in a matter of minutes. Network security is not compromised by VPN. Situations that would otherwise require field service calls, can now be handled in a matter of minutes using VPN assisted troubleshooting techniques.

Some of the first systems we designed were for water and waste water facilities using our own OEM hardware for control. Now, several decades later, our expertise covers many product lines from major vendors, with a growing legacy of institutional knowledge about how to make things work properly.