The Automation and Electronics, Inc. Water Injection Controller (WIC-II) is designed to monitor and control the injection of water at the wellhead and to monitor gas pressure and solar battery voltage levels. User configurable pressure and flow test programs are provided.

The WIC-II unit was developed specifically for injection well monitoring and control for oil field operations. It is fully configurable by the operator using an optional local interface, Personal Digital Assistant or portable computer. The unit is supplied with typical parameters ready for specific application tuning. Setup parameters may also be downloaded from a host computer. Software lockout notification provided by host and local interface.

Features

General

- Flow control with pressure override

- Pressure control with flow rate override

- Pressure fall-off test software

- Step rate and step pressure test software

- Direct turbine meter input

- Wedge Meter® or Coin Meter® Flow Measurement for H2O

- Manual valve override

- Local / Remote switch

- LEDs for easy status indication

- End element trend buffers

Options

- DUKS local operator interface

- RTU Link: Hand held with rugged serial port and interface software

- 12 VDC @ 10 A battery backed supply

- 10 A-H/day solar power supply

- Communications: Wire line to wireless Ethernet

Software

The Water Injection Controller application program is divided into the following modules:

- Elapsed time counter module

- LCD and key pad user interface module

- Time of day module

- Gauge off time module

- Analog sleep mode relay module

- Field input scaling and alarm handler module

- ESD control module

- Pressure fall off test module

- Step rate and step pressure test module

- Control valve module

- Control valve override module

- ESD and run-time totalizer module

- End element buffer module

- Watchdog timer with recovery

Specifications

| Mechanical | |

|---|---|

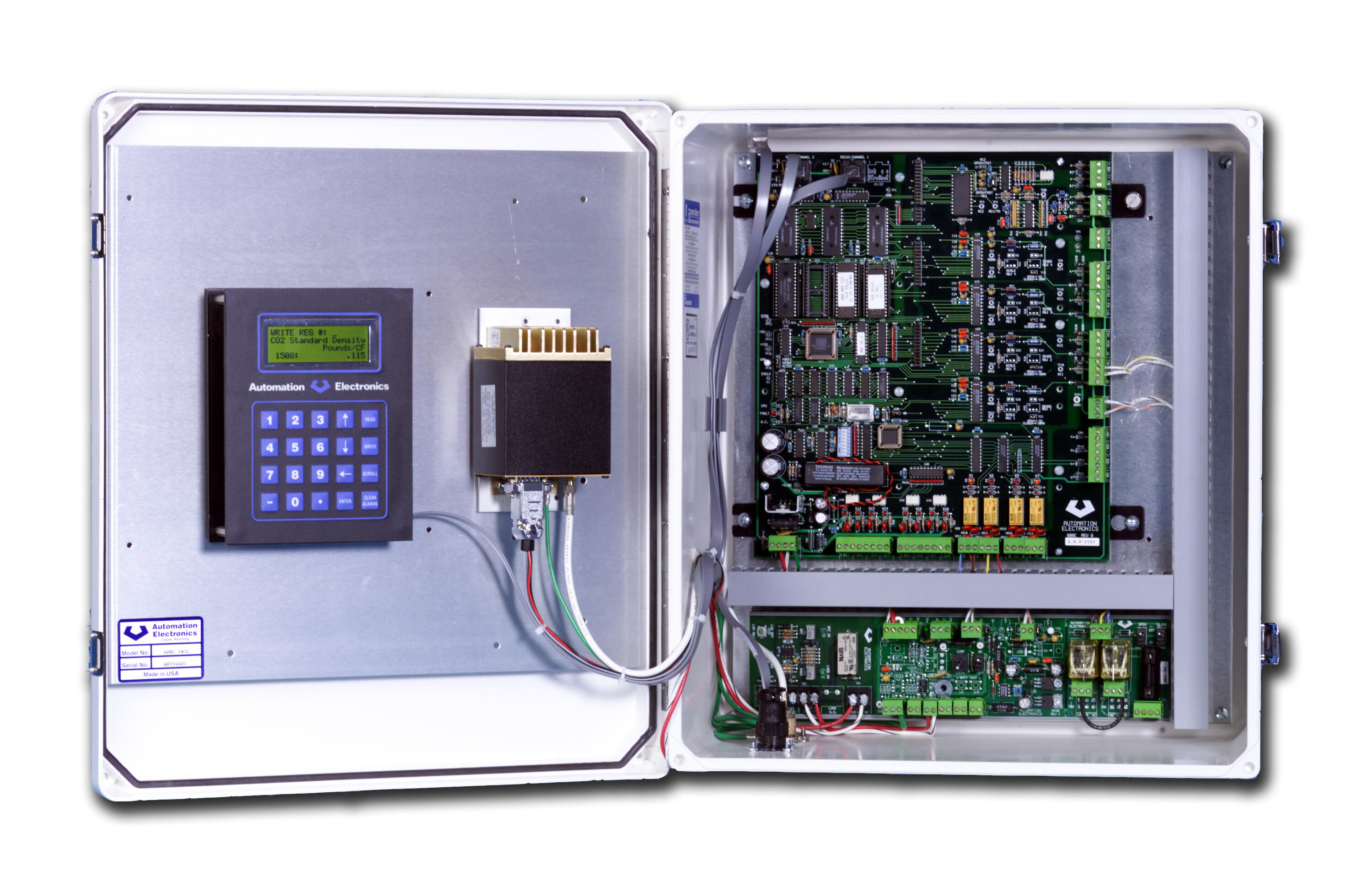

| Enclosure: | 18" x 16" x 8" NEMA 4X white fiberglass enclosure |

| Bailey controller hinge mounted replacement kits available | |

| Environmental | |

|---|---|

| Operating temperature: | -40 to 158 deg. F (-40 to 70 deg. C) |

| Relative humidity: | 5 to 90% non-condensing |

| Power required | |

|---|---|

| Typical: | 12 VDC, 24 VDC, 110 VAC and custom power supplies available. For most Permian Basin area controllers with radios, we recommend a solar power supply, 65 Watt panel and 100 A-H battery with a charging regulator, load shed module (LSM) and RTU power distribution board (RPDB) |

| CPU / Memory | |

|---|---|

| CPU: | 8 MHz CMOS 65C816, 16 bit |

| Memory: | 256 kB battery backed RAM, 256 kB EPROM |

| Input/Output | |

|---|---|

| Digital inputs: | Eight 1500 VDC optically isolated; 10 mA sense current single ended |

| Analog inputs: | Four 4-20 mA or 1-5 VDC (user selectable) non-isolated A/Ds |

| Relay outputs: | Two 7.5 A 30 VDC DPDT for valve actuator control and two 2 A 30 VDC DPDT |

| Turbine meter input: | One 30 mV to 10 Vpp, 10 to 3 kHz |

| Pulse input: | One optically isolated 0 to 2,500 Hz 12 V sink to ground @ 10 mA |

| Miscellaneous: | Optional multi-variable input through RS-485 bus (MODBUS RTU) |

| Communications | |

|---|---|

| Serial ports: | One RS-232 local operator interface port, one RS-232 communications port and one RS-232 / RS-485 port |

| Host communications: | 110 bps wire-line modems and licensed frequency, spread spectrum and wireless Ethernet radios supported to 19,200 baud |

Wedge Meter is a registered Trademark of ABB.

Coin Meter is a registered trademark of Preso Meter Corp.