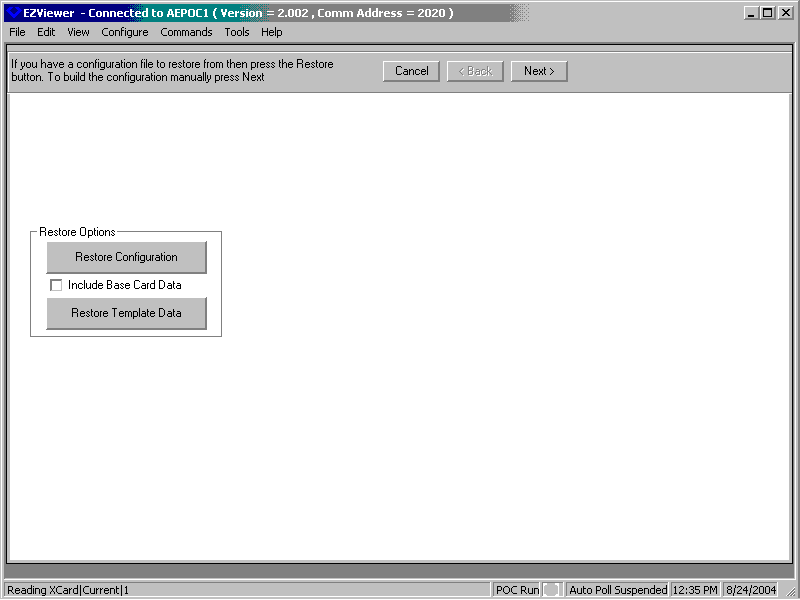

Templates

The AEPOC provides the ability to save set up parameters to disk and load these back into existing or new units as needed.

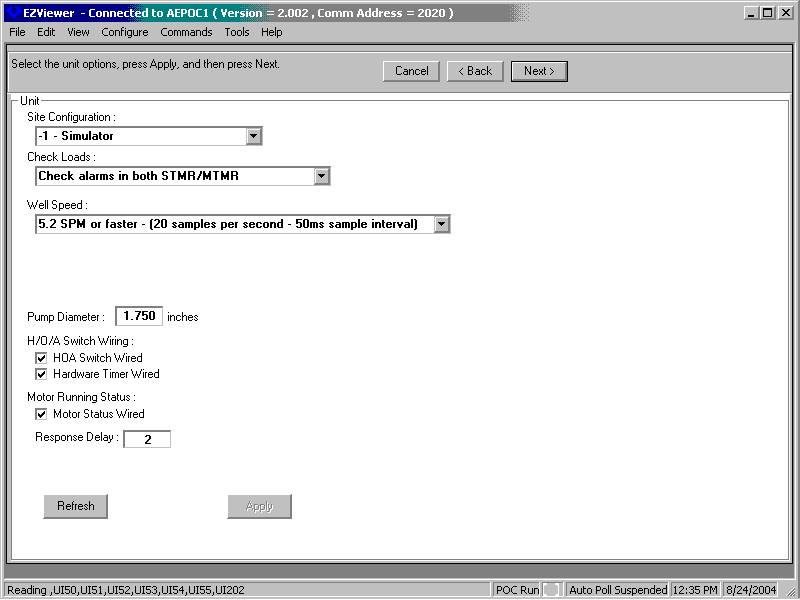

Site configuration

Most customers elect to have a special group of set up parameters configured in the controller firmware to provide a generic load that can get wells mostly configured in one simple step. The site screen allows these to be selected.

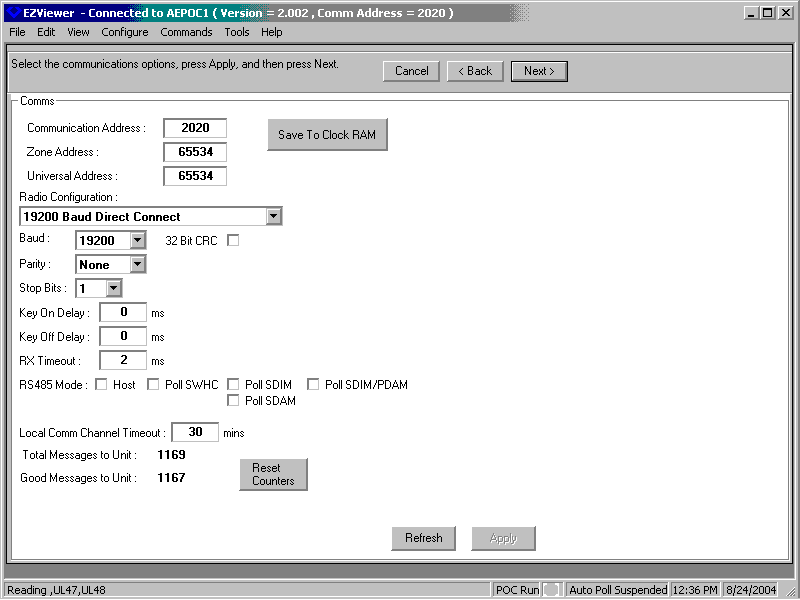

Communications

Communications configuration and display are configured through this interface.

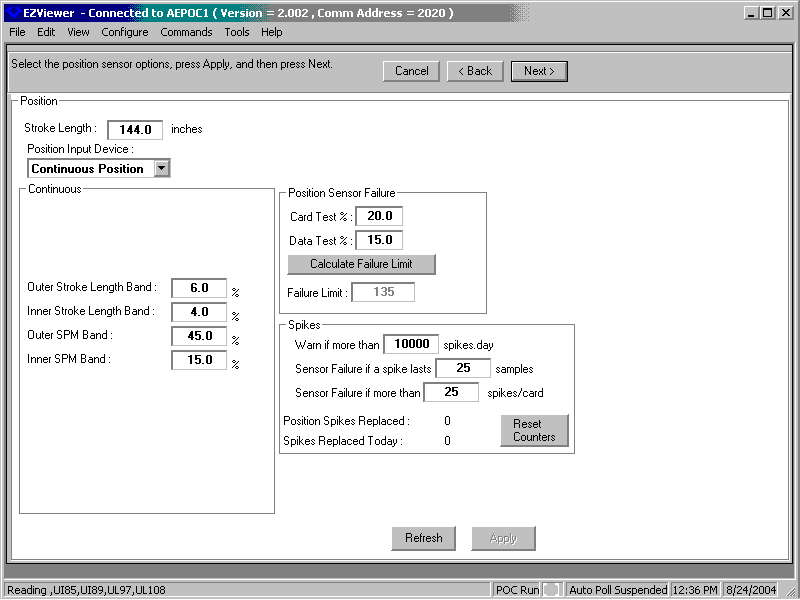

Position inputs

The AEPOC can handle continuous, position switch, and both damped and undamped inclinometers. These are selected here and some basic alarm bounds can be tweaked if needed from the standard defaults.

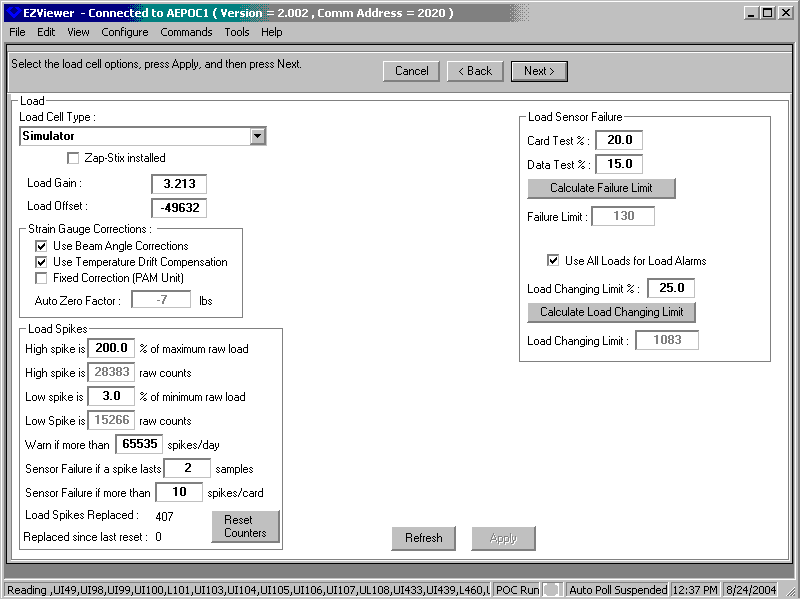

Load inputs

The AEPOC can handle normal polished rod load cells of various ranges, custom ranges, and strain gauges. These are configured here.

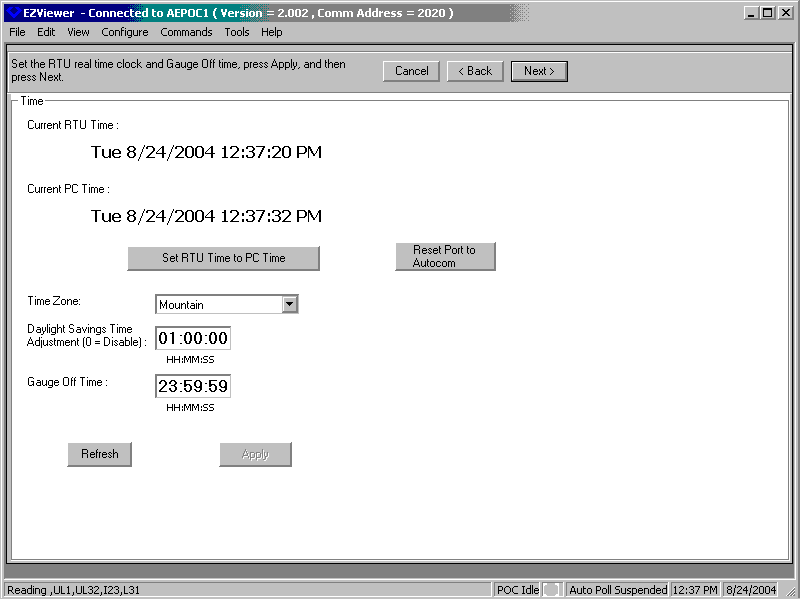

Time of day

The time zone information is usually set up by the site wizard, but basic configuration can also be done here. In addition, other registers can be altered in case Congress changes the daylight savings time rules again. Units can be located in the Southern and Northern hemisphere (specified by a latitude register) and East or West of Greenwich. Standard time zones are supported around the world and custom offsets can be applied if a standard time zone doesn't fit your location.

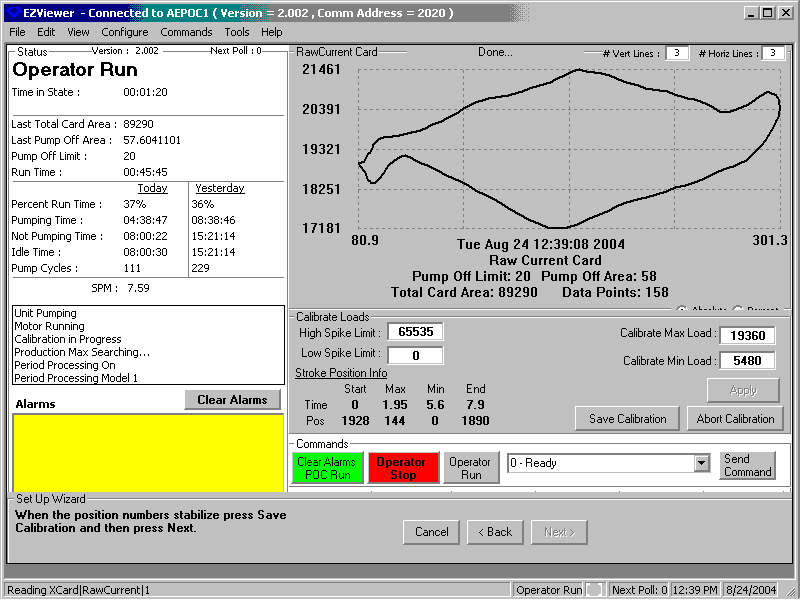

Load cell calibration

Load cell inputs are calibrated to known minimum and maximum loads via this screen.

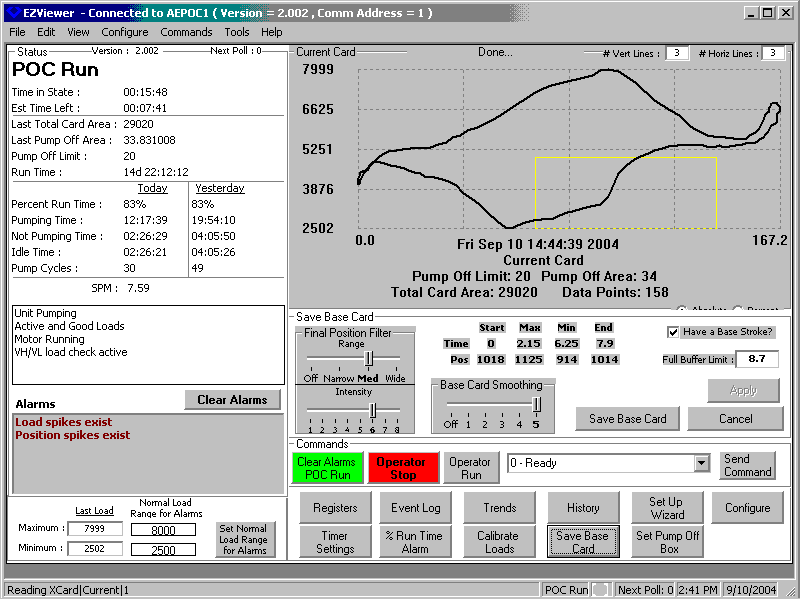

Base stroke configuration

Good base strokes are essential for certain deep rod part and high work alarms to function correctly. This screen allows the operator to choose a good base stroke to use for this function.

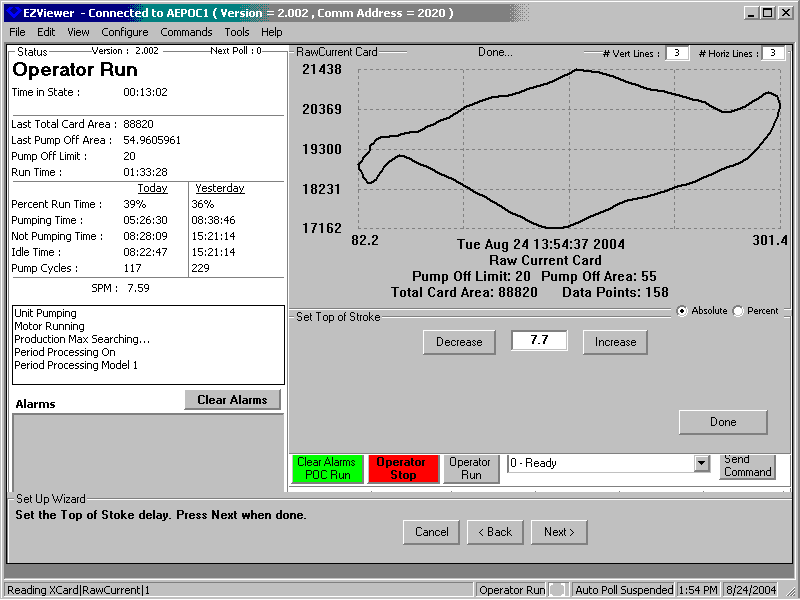

Top of stroke configuration

When position switches are used, it is necessary to synchronize the top of stroke to the previously saved base stroke which usually has used a temporarily attached position pot as a reference. This allows the operator to move the top of stroke signaled by the position switch forward or backwards in time to line up with the base card.

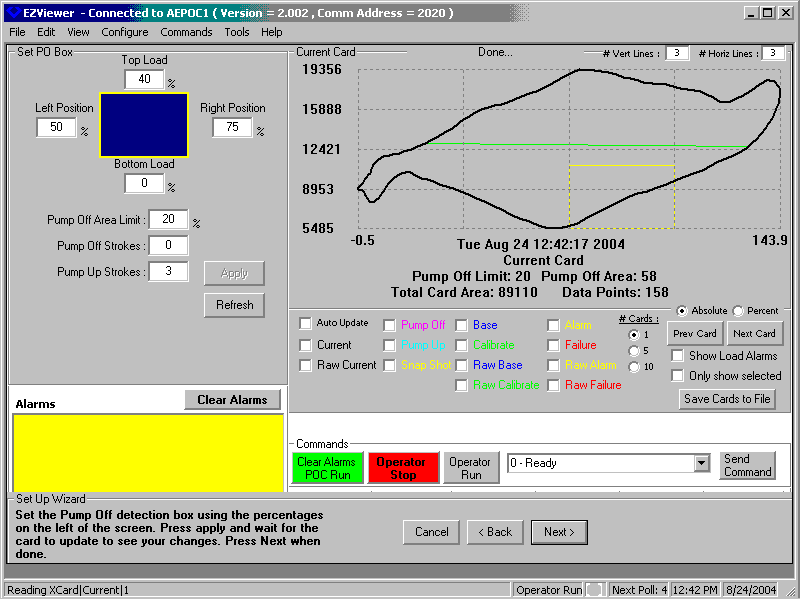

Pump off rectangle configuration

Our AEPOC determines pump off by examining the card area in a user positioned rectangle. This reduces false pump offs due to spiky load or position data. The rectangle's size and the area required to signal a pumped off condition are configurable.

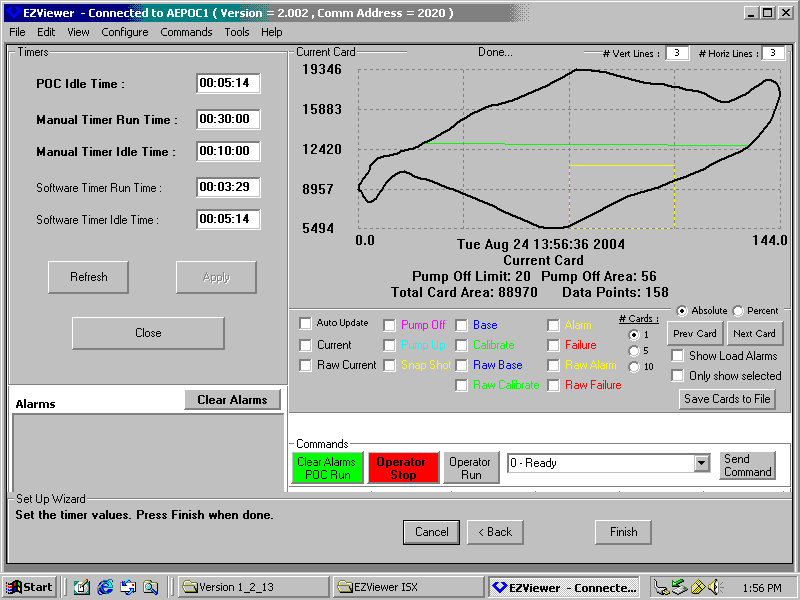

Operating configuration

The basic run and idle times for manual timer overrides are configured on this screen. In addition, idle times for software timer failure modes and basic pump off operation are set here.